- Bend from 3/8″ to 16″ (depending on model) legs in metal sheets up to 24g. Softer metals (aluminum) up to 040

- Bend inside and outside radii ( model VP 10 and VP 16 )

- Bend unlimited lengths of metal on the job or in the shop. No more limitations to only 8 feet.

- Flexible manufacturing process

- Easy customization and freedom when it comes to giving shape to a profiled section even at the jobsite

- Shorter travelling time

- The required tools are small and affordable

- Shorter production times imply prompt delivery and a faster completion of the job

- Optimal leverage making work even more easy

- economic price

- Flexible manufacturing process

- Easy customization and freedom when it comes to giving shape to a profiled section even at the jobsite

- Shorter travelling time

- The required tools are small and affordable

- Shorter production times imply prompt delivery and a faster completion of the job

- Optimal leverage making work even more easy

Mobile Beading Tool for sheets and panels.

Standing Seam Panels up to 38 mm and many other work pieces. On site or in the workshop.

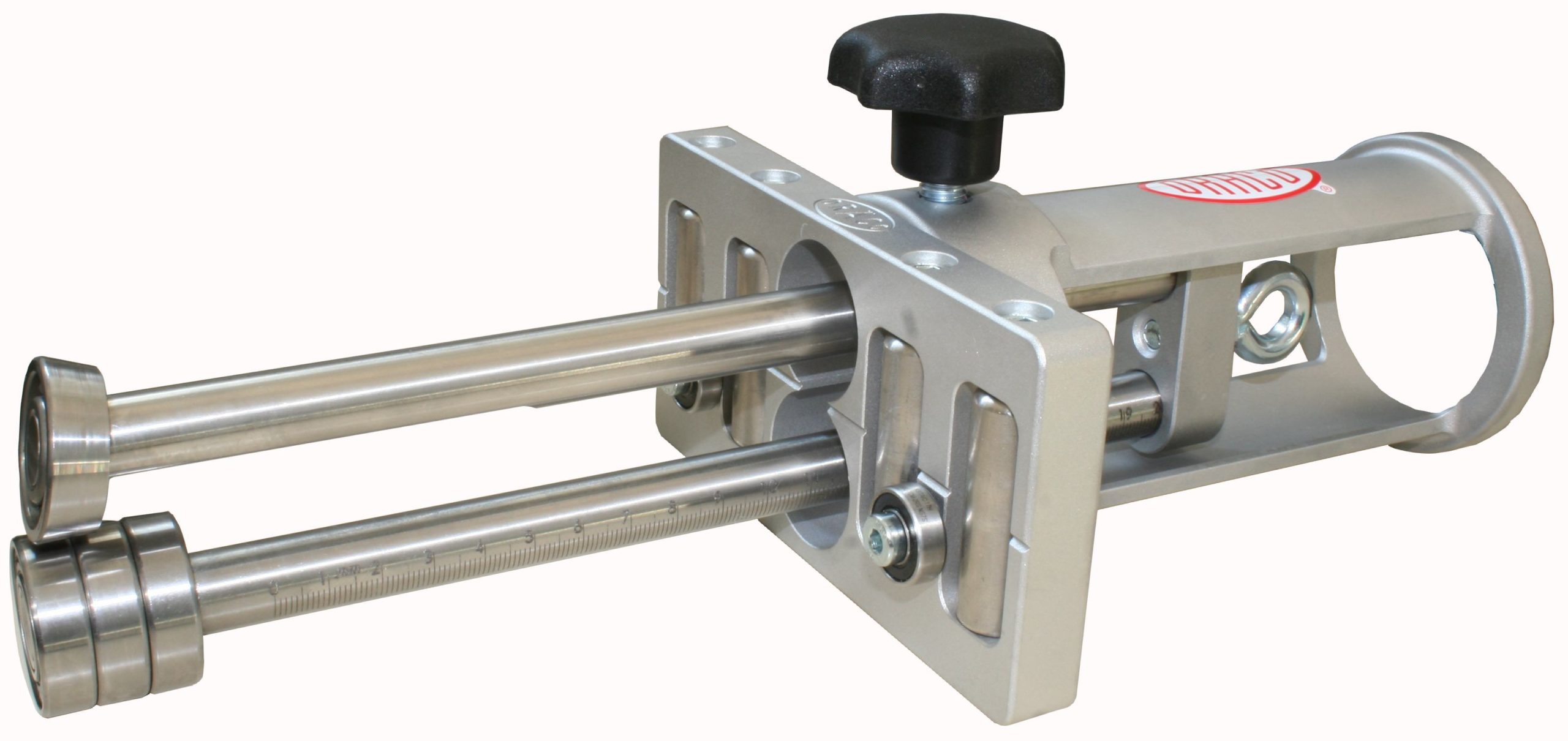

The Panel Bender PB 250 Plus is a light, portable device with a manual drive. Generates flat beads in sheet metal, coulters and folded or pre-profiled material.

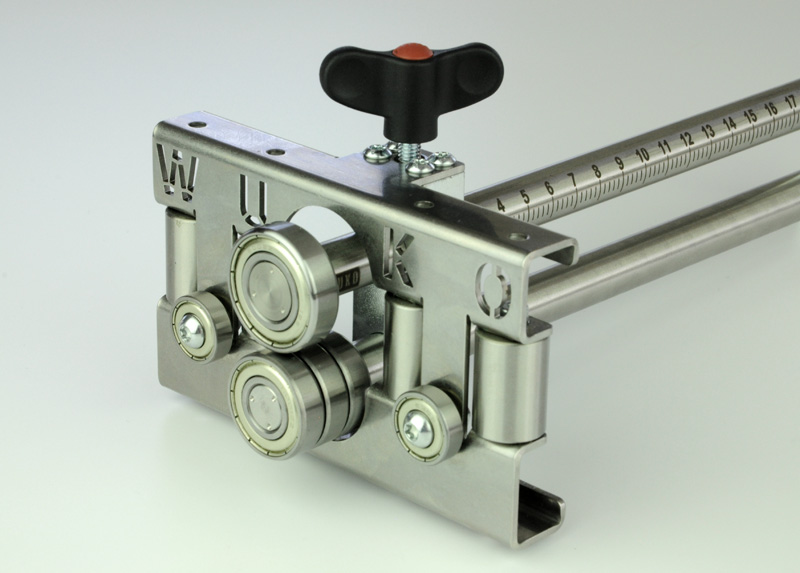

The manual feed of the top roller enables sensitive processing of the workpieces and the processing of complex shapes. The workpiece is not only guided through a stop plate, but also through vertically arranged hard guide rollers and ball bearings, which ensure the repeatability of recurring workpieces.

- Interchangeable form rollers

- Beading or offset depth up to approx. 3.5 mm

- Ideal for stiffening standing seam panels

Capacity, ca:

| Aluminium, Copper, Zinc: | 1,0 mm (18 ga.) |

| Steel | 0,8 mm (20 ga.) |

| Stainless steel | 0,5 mm (23 ga.) |

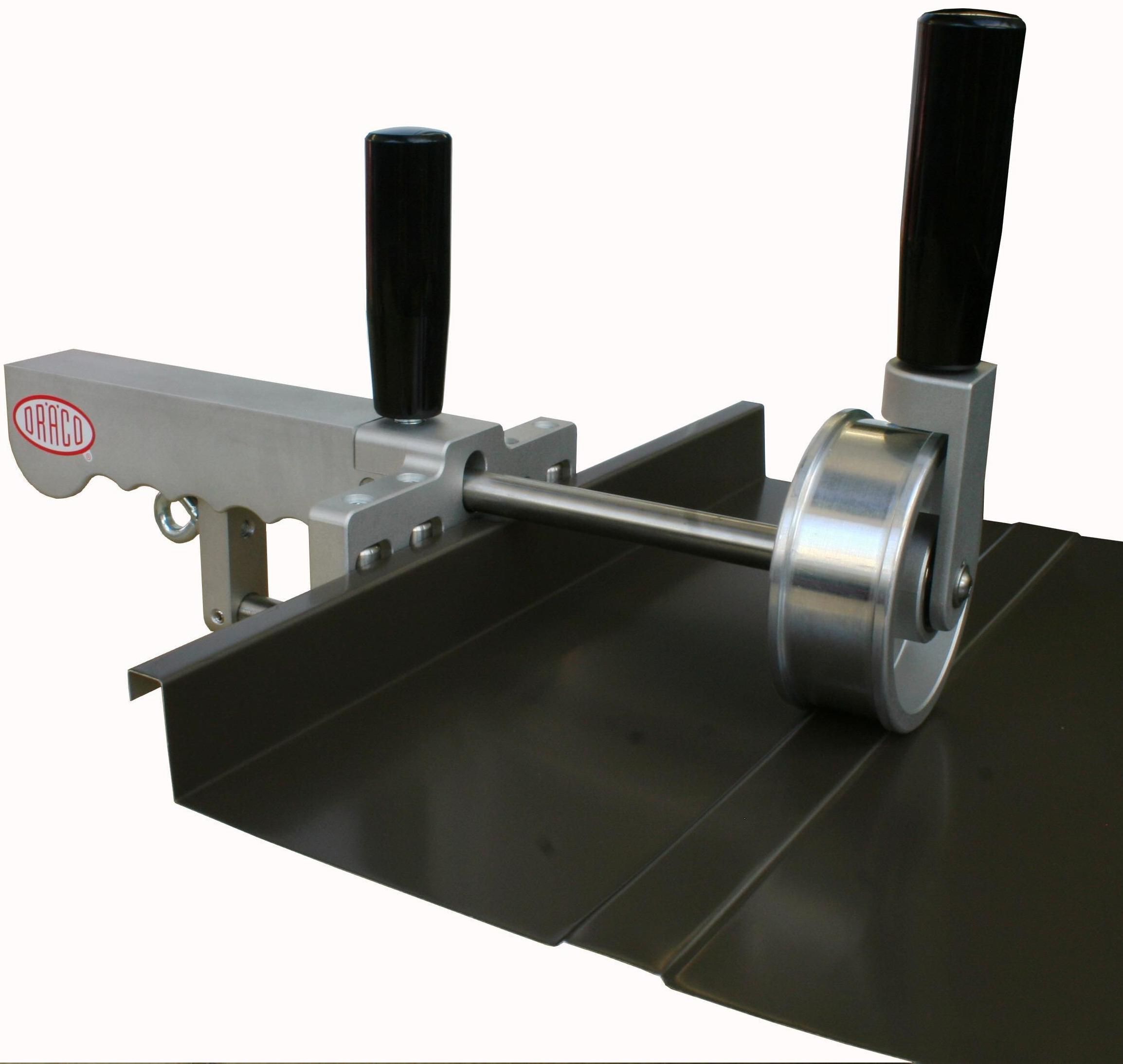

Mobile Beading Tool for sheets and panels.

Standing Seam Panels up to 38 mm and many other work pieces. On site or in the workshop.

The Panel Bender PB 250 Plus is a light, portable device with a manual drive. Generates flat beads in sheet metal, coulters and folded or pre-profiled material.

The manual feed of the top roller enables sensitive processing of the workpieces and the processing of complex shapes. The workpiece is not only guided through a stop plate, but also through vertically arranged hard guide rollers and ball bearings, which ensure the repeatability of recurring workpieces.

- Generates round beads

- Interchangeable form rollers

- Beading or offset depth up to approx. 3.5 mm

- Ideal for stiffening standing seam panels

Capacity, ca:

| Aluminium, Copper, Zinc: | 1,0 mm (18 ga.) |

| Steel | 0,8 mm (20 ga.) |

| Stainless steel | 0,5 mm (23 ga.) |

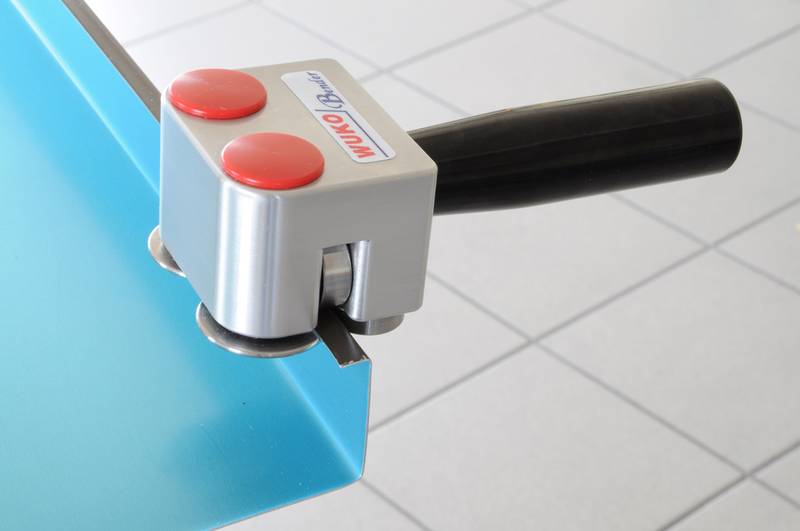

Bending a right angle of 90° to max. 180°. Angle height from 8 – 40 mm/ 0,31“-1,57“. Perfect for eaves, valley channels, cross seams, alterations, gutter flashings and many more. Max. metal thickness up to 1 mm/19ga. (depending on material)

bending from 0°-90°, bending height 5-350 mm

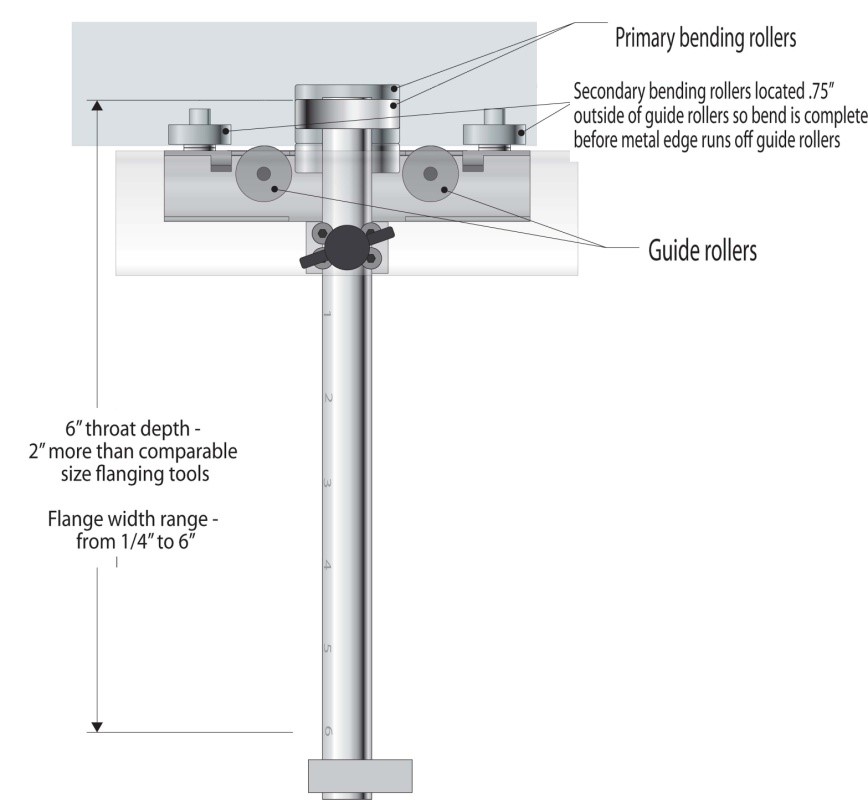

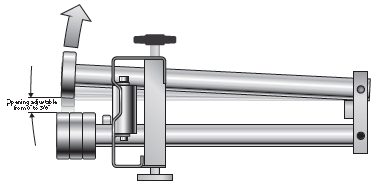

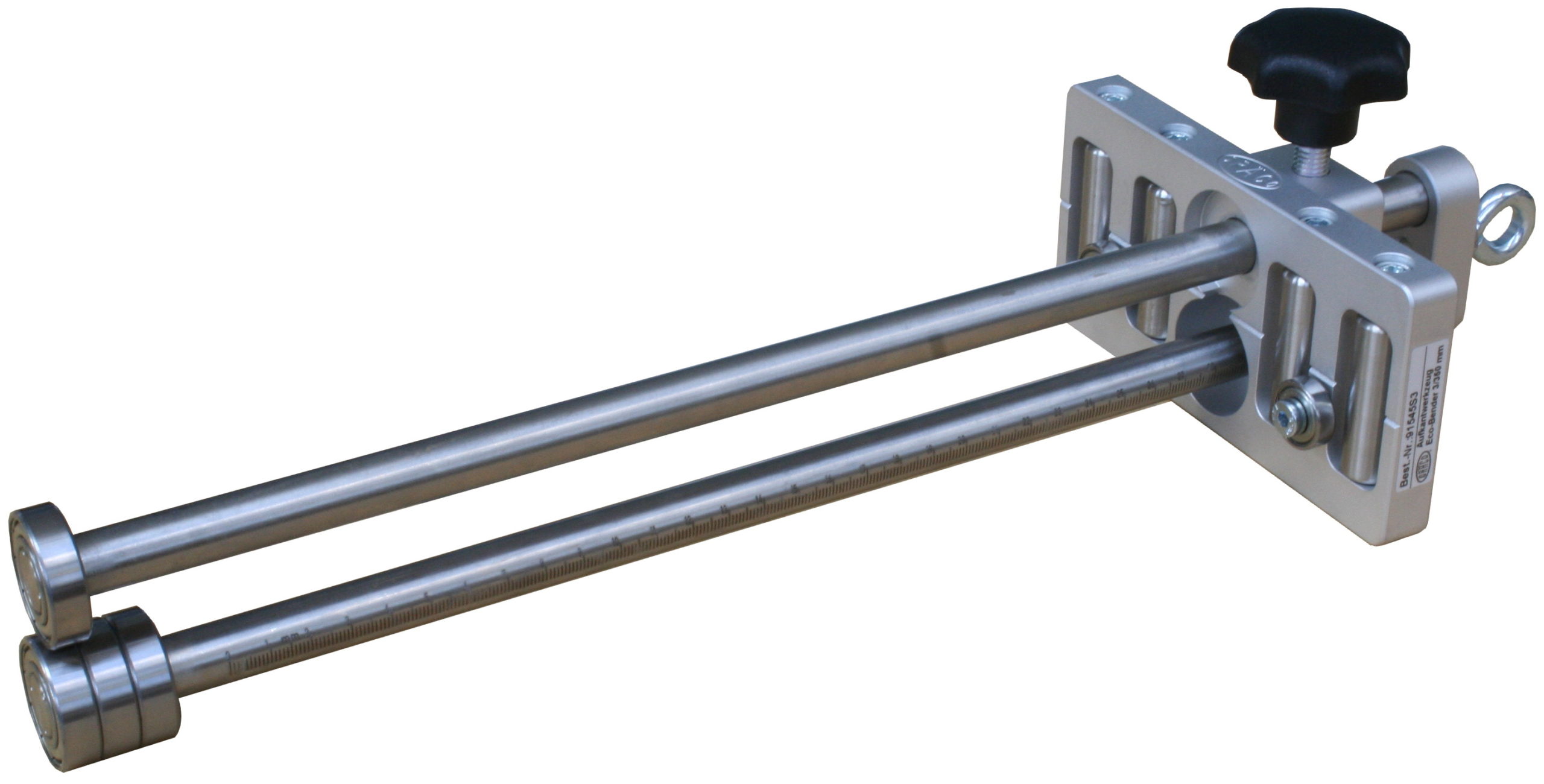

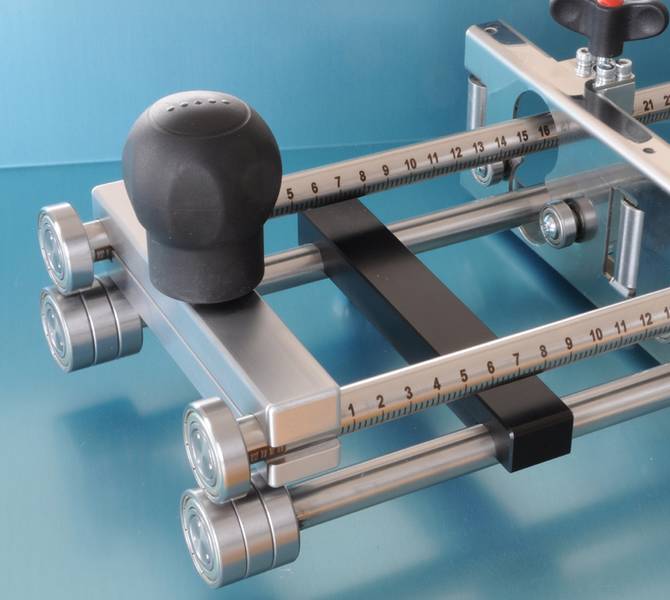

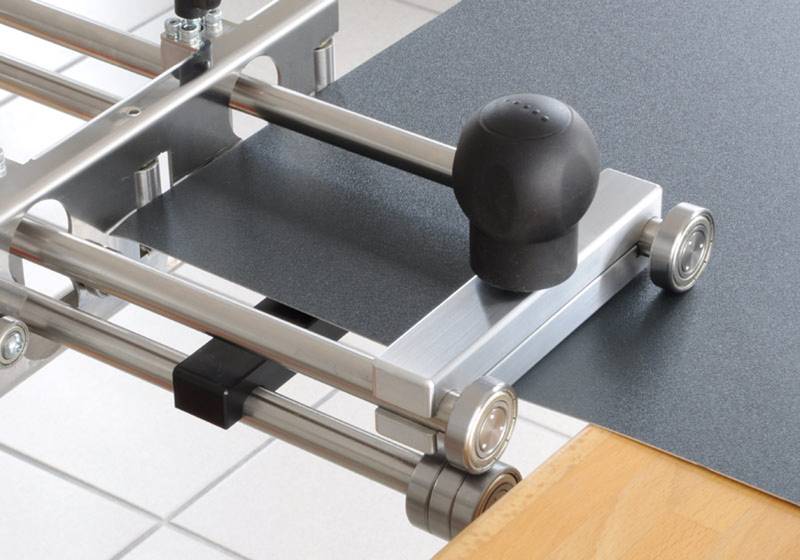

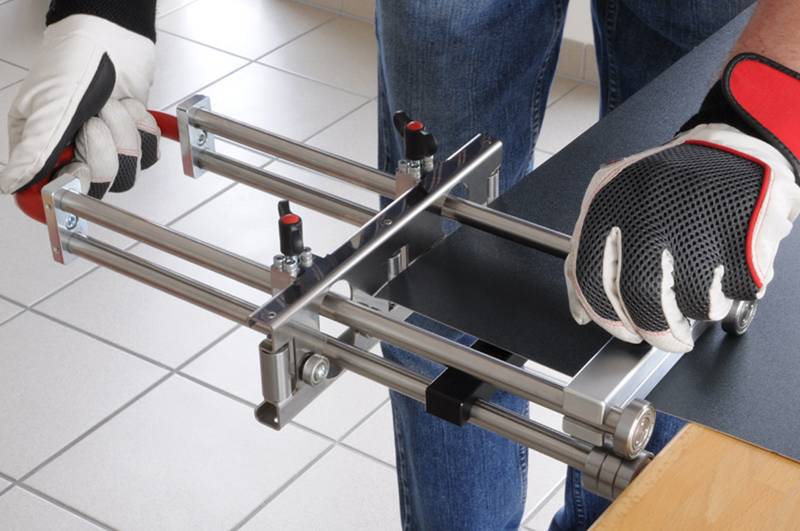

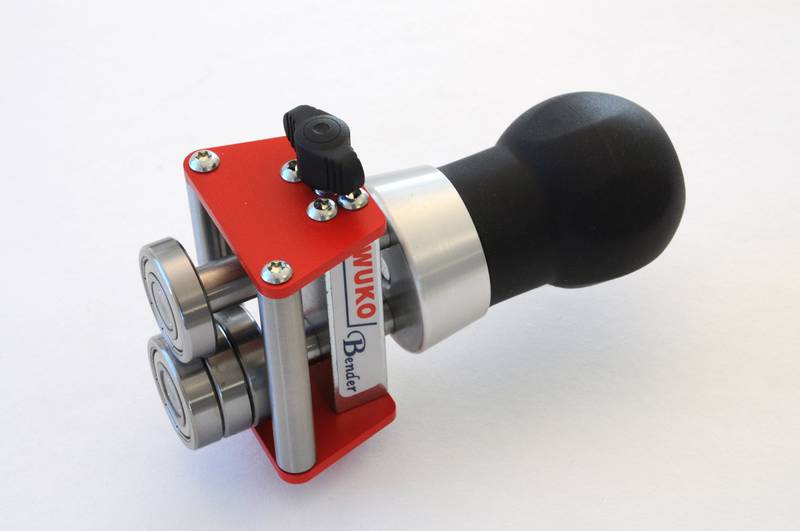

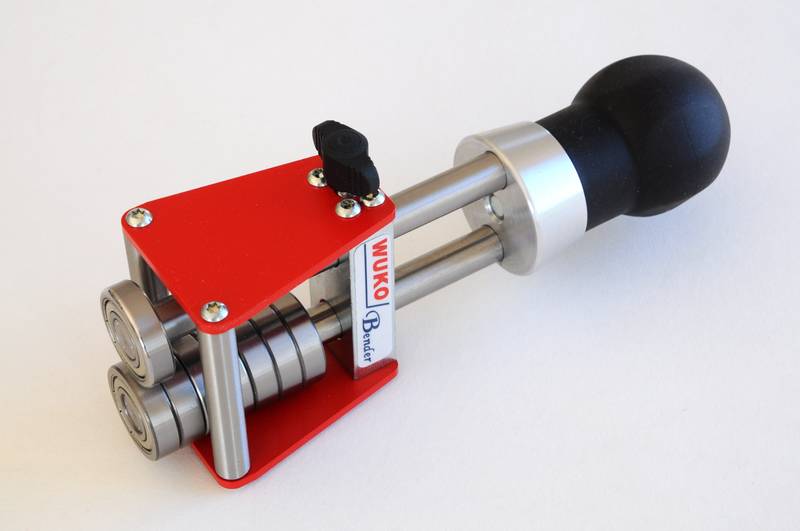

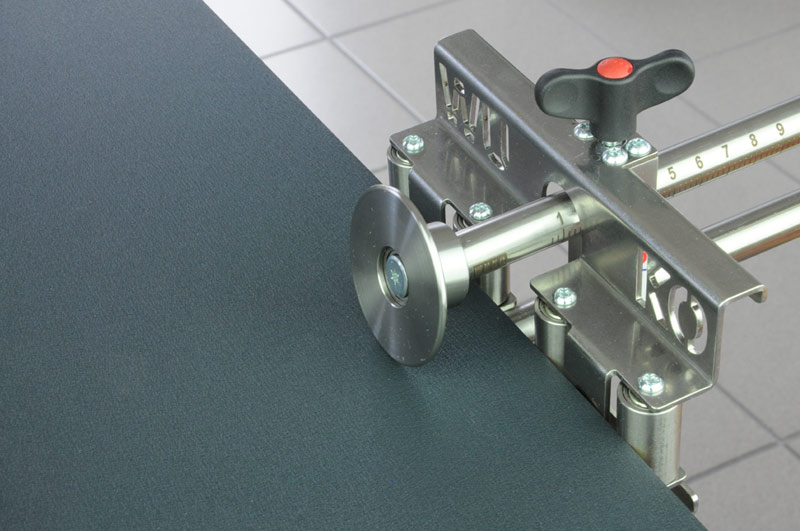

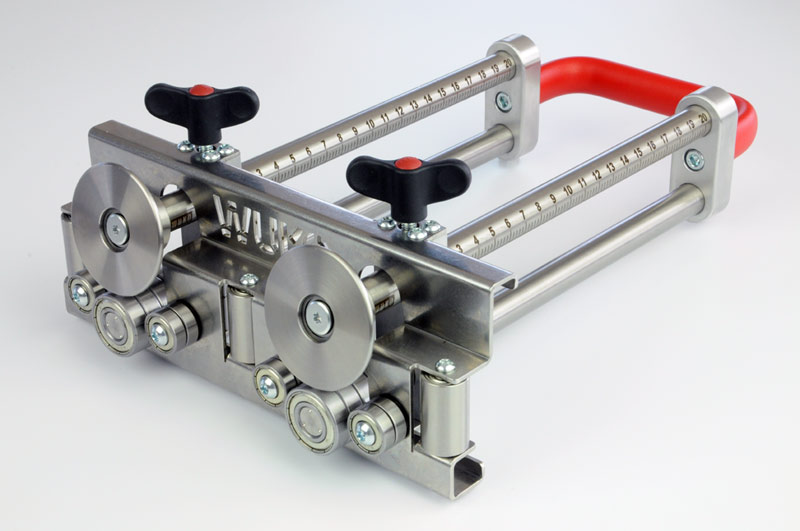

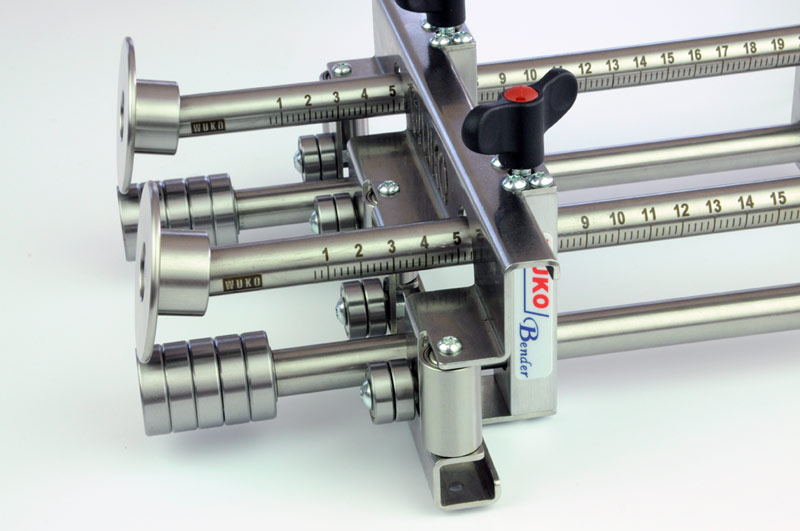

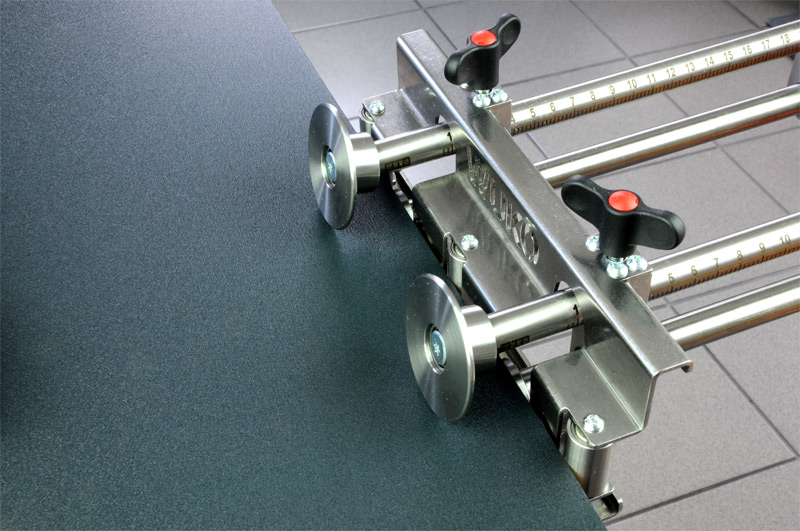

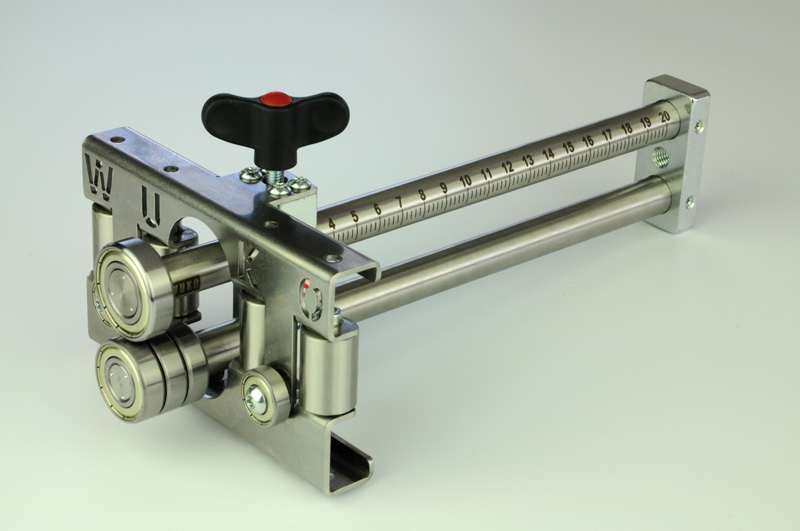

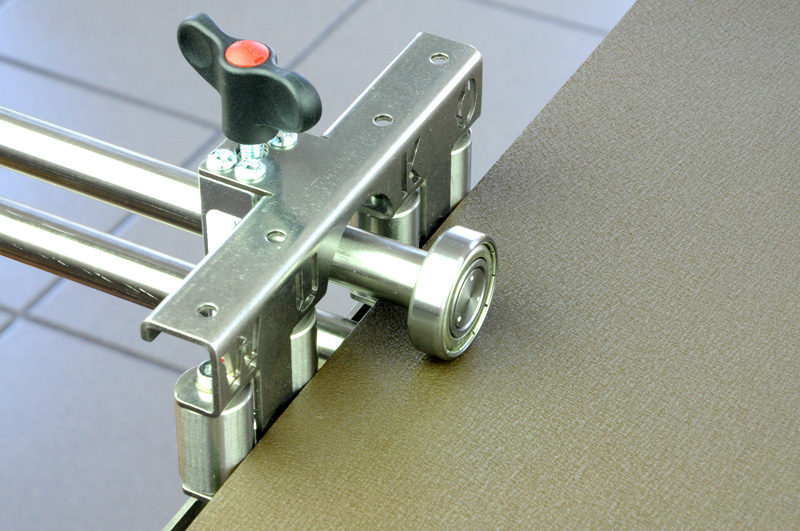

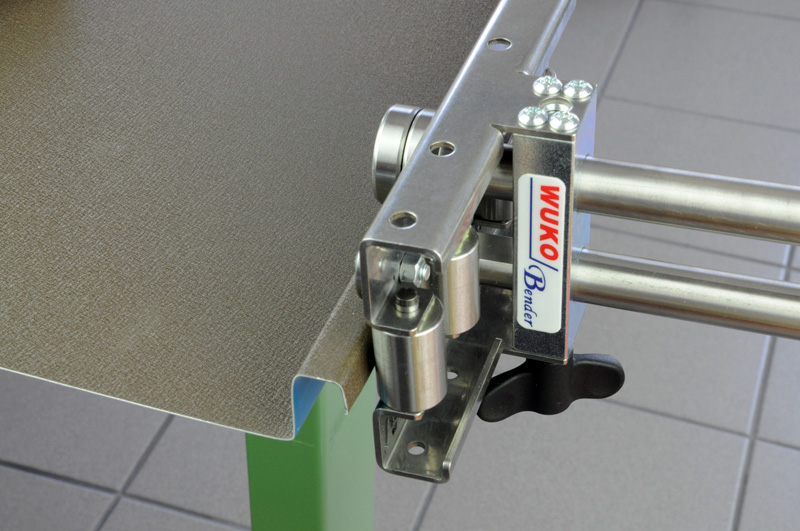

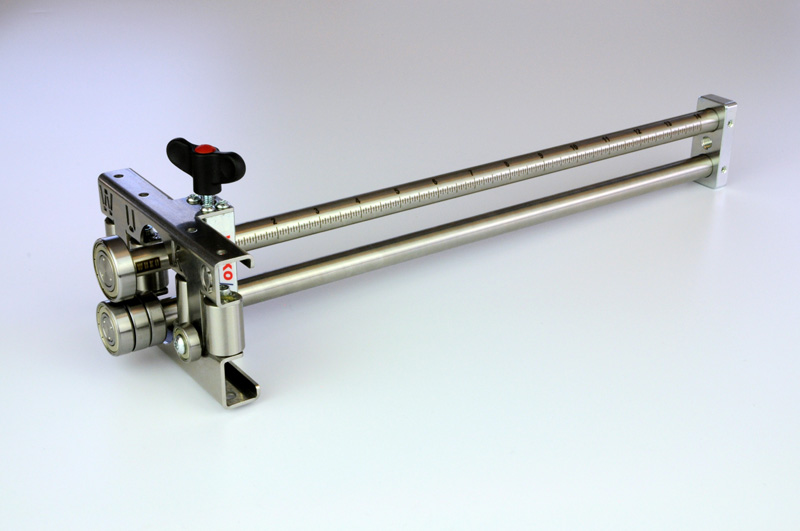

Universal mobile bending tool to bend and form all kind of materials straight, concave or convex.

With 4 guide rollers the EcO-Bender offers you a stabil guidance and an easy handling.

This bender forms many profiles. Bending up and down, making under and over cloak (male and female), standing seam and many more. Bending height is continously adjustable (graduation in mm and inch). Inner and outer radii are possible, max. bending height depends on radius!

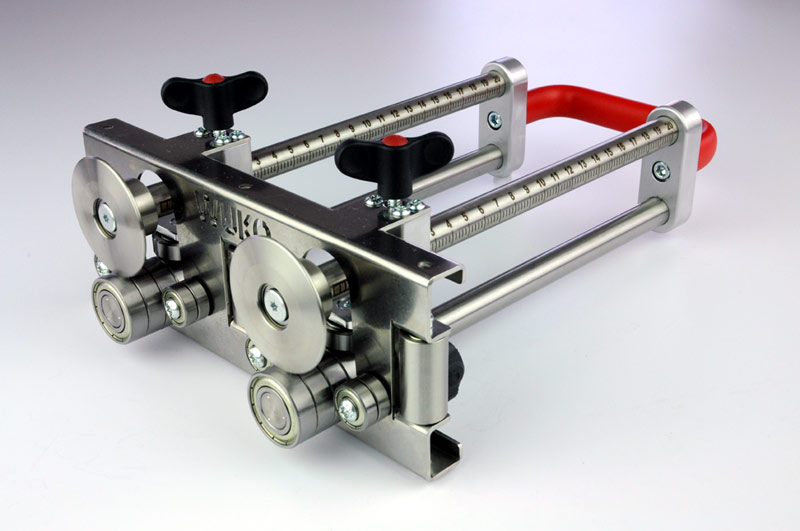

By using an optional adapter two EcO-Benders can be connected to a Duo-EcO-Bender. This one is extremely comfortable when working on long and straight metal sheets.

Technical data:

- Bending capacity: 0.80 mm / 0.031″ (for all common materials)

- Throat Depth: 0 – 6.5 cm / 0 – 2 1/2″

- Weight 1.46 kg / 3.22 lbs

Technical Data:

- Max. bending height: 40 mm / 1.57″ (depending on material)

- Min. bending height: 8 mm / 0.31″ (depending on material

- Bending capacity: 0.80 mm / 0.031″ (for all common materials)

- Weight 2.72 kg / 6.0 lbs

Technical Data:

- Max. bending height: 32 mm/1 1/4″ (depending on material)

- Min. bending height: 8 mm/0.31″ (depending on material)

- Bending capacity: 0.80 mm/0.031″ (for all common materials)

- Weight 0.76 kg / 1.7 lbs

Technical Data:

- Max. bending height: 200 mm / 8″

- Min. bending height: 5 mm / 0.2″

- Bending capacity: 0.80 mm / 0.031 in (for all common materials)

- Weight 2.68 kg / 5.9 lbs

Technical Data:

- Max. Bending capacity: 0.80 mm / 24 gauge (for all common materials)

- Bending height: 6 – 200 mm / 0.24 – 8″

- Weight: 3,02 kg / 6,7 lbs

Technical Data:

- Bending height: 5 – 12 mm / 0.2 – 1/2″

- Bending capacity: 0.80 mm / 0.031″ (for all common materials)

- Weight 0,68 kg / 1.5 lbs

Technical Data:

- Max. bending height: 23 mm / 0.91″ (depending on material)

- Min. bending height: 8 mm / 0.31″ (depending on material)

- Bending capacity: 0.80 mm / 0.031″ (for all common materials)

- Weight 0.63 kg / 1.39 lbs

Technical Data:

- Max. bending height: 23 mm / 0.91″ (depending on material)

- Min. bending height: 8 mm / 0.31″ (depending on material)

- Bending capacity: 0.80 mm / 0.031″ (for all common materials)

- Weight 0.63 kg / 1.39 lbs

Technical Data:

- Bending capacity: 0.80 mm / 24 gauge (for all common materials)

- Bending height: 6 – 350 mm / 0.24 – 14″

- Weight: 1.95 kg / 4.30 lbs

Technical Data:

- Bending capacity: 0.80 mm / 24 gauge (for all common materials)

- Bending height: 6 – 200 mm / 0.24 – 8″

- Weight 2,75 kg / 6,06 lbs

Technical information:

- bending capacity: 0.80 mm / 24 gauge ( for all common materials)

- bending height: 6 – 350 mm / 0.24 – 8″

- weight: 3,59 kg / 7,91 lbs

Technical Data:

- Max. bending height: 200 mm / 8.0″

- Min. bending height: 5 mm / 0.2″

- Bending capacity: 0.80 mm / 0.031″ (for all common materials)

- Weight: 1’49 kg / 3,28 lbs